Plastic-metal composite parts are currently becoming more and more interesting and important in order to meet the demand for “smaller, lighter and more compact”. They are important components for switching, control and connection functions in electro-mechanical and electronic systems. As a leading manufacturer of electromechanical assemblies, DODUCO offers you flexible solutions of the most varied complexity – from development to series production. Even the integration of electronic components and thus the creation of an extensive range of functions can take place at DODUCO.

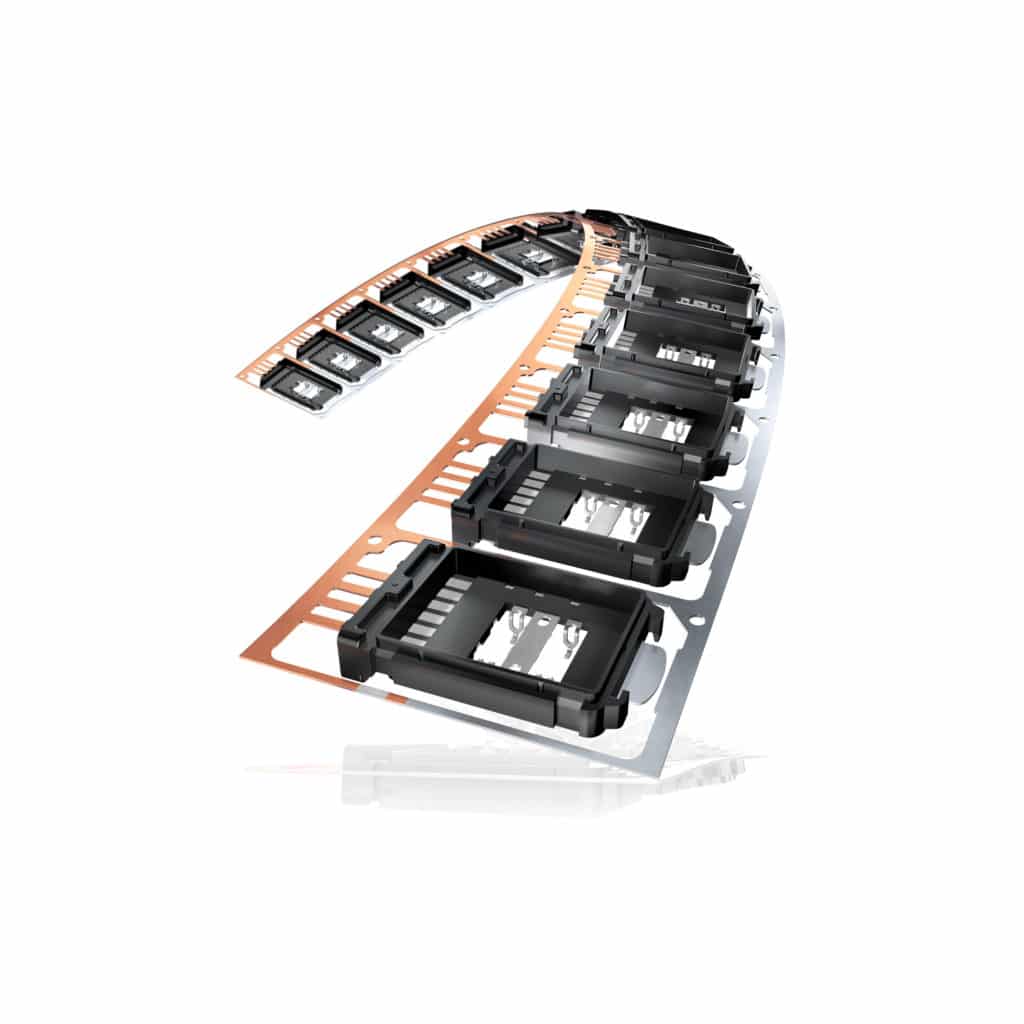

Through the combination of plastic, metal and contact surfaces, we develop an overall solution, reduce the number of interfaces and contribute to cost savings. For these reasons, many automotive supply companies actively use DODUCO‘s know-how. Depending on the product, we manufacture using assembly technology, manufacture applications in hybrid housings or implement solutions using reel-to-reel technology.

Where electronics and mechanics meet – DODUCO is there:

Semiconductors in hybrid frames for control of vehicle engines, wind and solar power systems.

Strip molded contact parts in air bag sensors, circuit breakers, household installations, Tip switches for different switching desk applications, in electric toothbrushes and various household appliances.

Use of complex assemblies – of intelligent vehicle-mirror adjusting units to innovative control units in cooling water and oil pump systems of transmission control systems

Binding technology between plastic-metal composite-assemblies to the electronics by:

Bonding on the AlSi1 surface, Various soldering processes for tinned surfaces, Various welding technologies, Use of flexible press-fit zones

Today’s machines can “think”. More than thirty years ago, this was only a dream. Now it has become a reality, made possible by a revolution in the field of semiconductors. Semiconductors and sensors help to provide precise control of all types of machines, from automotive engines to machine tools, allowing them to make continuous adjustments through the acquisition, analysis, and control of environmental data. But the semiconductor “brain” cannot do all this alone. It needs a housing that can act as the interface to the machine.

Hybrid frames have their application here. These frames act as an interface for integrated electronics that transfer both: signals and energy. The signal transfer is accomplished through aluminum or gold wire bonding. The hybrid frame also houses selectively plated, custom connectors, that enable the completion of the signal transfer. DODUCO is a market leader in hybrid frame engineering, especially for automotive applications. We are the largest European source for cladded aluminum, the preferred surface for aluminum wire bonding. We also offer a variety of other plated and clad surfaces such as silver, nickel, gold palladium and tin.

Through decades of experience in the manufacture of hybrid frames, DODUCO can offer outstanding applications advice in the selection of the most suitable contact surfaces and surface treatments. Additionally, our product development engineers will custom design a process to support our customers in all phases of hybrid frame construction, resulting in the highest quality hybrid frames at a favorable cost.

From design consultation, to development and production, DODUCO provides its customers with a complete capability package for hybrid frames, used to provide energy for machines and equipment.

Increased functionality means increased complexity in a large variety of automotive, consumer and telecommunication applications. As more parts are introduced into the assembly process, the complexity of the manufacturing processes also increases, demanding higher quality requirements.

Strip molded contact parts from DODUCO can reduce this complexity. Many components assembled from two or more parts can now be integrated in a single functional assembly that consists of one stamped contact part over-molded in plastic material. Combining the stamping and molding technologies into an automated, inline manufacturing process, enables DODUCO to maintain the highest quality standards while optimizing efficiency. This specialized approach to insert molded contact parts allows the attainment of tighter manufacturing tolerances that far exceed the standard for conventional assembly techniques.

In applications where strip molding is not possible, we can offer a fully, or semi-automated assembly process. The latest automation technologies are used to assemble complete functional units from discrete components.

These technologies promote reliable and repeatable results, as well as increased functionality. Additionally, electronic components can be integrated in this process, increasing yet again, the level of product functionality.

DODUCO Technical Solutions GmbH

Breite Seite 1

74889 Sinsheim

Germany

DODUCO Technical Solutions GmbH located in Sinsheim in Germany is a leading manufacturer of electromechanical components using plastic-metal composite technology and offers flexible solutions of varying complexity from the development stage through to mass production. Plastic-metal composite components are small, light, and compact assembly units for the switch, control and connection functions in electromechanical and electronic systems. DODUCO can even handle the integration of electronic components, thereby serving a vast range of functions. By combining plastics, metals, and contact surfaces, we create an almost interface-free total solution for our clients.